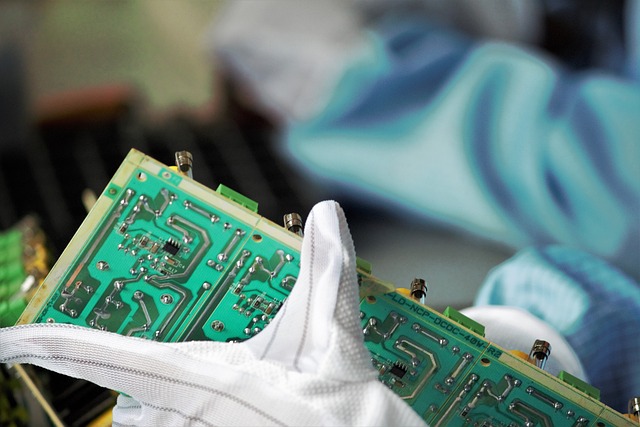

Double Sided PCBs

At PCB Trace Technologies Inc, we make all types of double-sided printed circuit boards for the electronic industry. As opposed to the single-sided boards, double-sided printed circuit boards are in greater demand, as they effectively reduce the area of the board required. You can think of a double-sided board as two single-sided PCBs placed back to back, with vias interconnecting the two copper sides where necessary.

Even though more expensive compared to the single-sided board, the electronics industry prefers double-sided printed circuit boards as its two layers provide more channels for routing traces between components. Consequently, designers can pack in more components per unit area of the board, leading to a smaller overall board size for the same or better functionality.

We make all types of double-sided PCBs, including class 1, 2, and 3 types. Therefore, if you are looking for a special type of double-sided board for your mission-critical application, do not worry, as we have you covered.

What is a Double-Sided PCB?

The construction of a double-sided PCB is very similar to that of a single-sided board. Both have an insulating rigid core or substrate. The difference between the two is in the number of copper circuits on the board. While a single-sided board has a copper foil covering only one of its sides, the double-sided PCB has copper foil covering both its sides. Consequently, two copper circuits are possible on each double-sided PCB, which allows it to house a more complex electronic circuitry, thereby increasing the utility of the board.

An additional feature in double-sided sided boards is the via. These are plated through holes electrically joining the circuit from one side of the board to the other. As the designer can relegate interconnecting tracks between components to the lower side, the top side of the board carrying components can have much higher density.

Applications of Double-Sided Boards

Because of the many benefits of double-sided PCBs, they are very popular in the electronic industry. The industry uses them for entertainment, commercial, and health-care applications like:

- Power Conversion

- UPS Systems

- Instrumentation

- Control Systems

- Power Supplies

- Televisions

- HVAC

- Printers

- Hard Drives

- Vending Machines

- Traffic Systems

- Audio Equipment

And many more.

When to use Double-Sided PCBs

Anytime you want to save money, time, and or increase the capabilities in your application, you can use double-sided PCBs. At PCB Trace Technologies Inc, we will support you in all your requirements with our quality products, low lead times, low turn-around times, and reasonable pricing.

Advantages of using Double-Sided PCBs

There are numerous benefits to using double-sided PCBs in electronic applications. One of the primary benefits is they help to reduce the overall project cost. Although more expensive compared to a similar sized single-sided board, the effective cost is much lower. This is because the presence of the second layer allows the designer to increase the component density, thereby reducing the overall size of the board.

The ability of a double-sided board to handle higher complexity circuits makes them a better choice than single-sided boards do. While single-sided boards can mount components only on one side, it is possible to mount components on both sides of a double-sided board.

Using a double-sided board helps in improving the EMI/EMC performance of the circuit. The primary requirement for improving EMI/EMC performance is by shielding and grounding, which a single-sided board cannot do effectively. On the other hand, a double-sided board can provide a very effective shielding by using one of its layers as a ground or power layer.

For the above reasons, if you plan on using a double-sided board for your next project, PCB Trace Technologies Inc will provide you with all the assistance and backup you need to get your double-sided PCB in time. Contact PCB Trace Technologies Inc today with your requirement.