HDI Capability

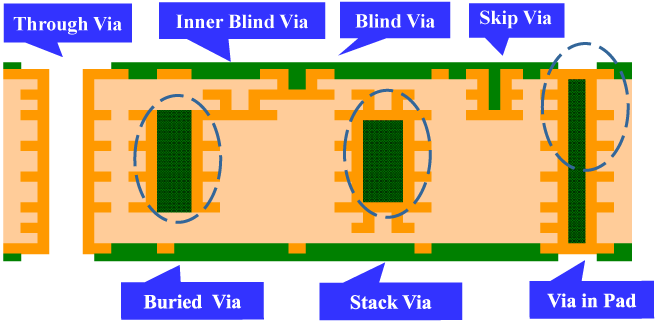

HDI Technology in Hole

High Density Interconnection

|  |  |  |  |  |

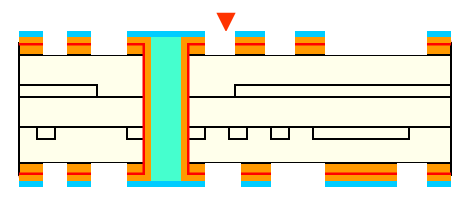

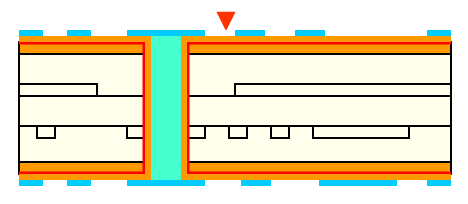

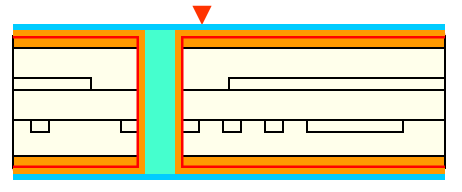

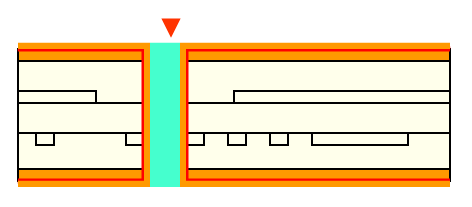

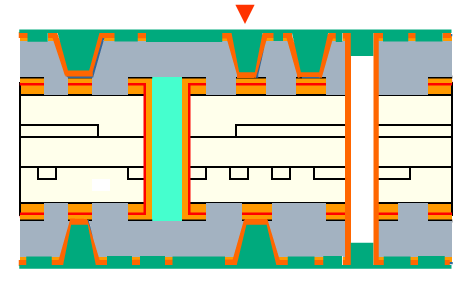

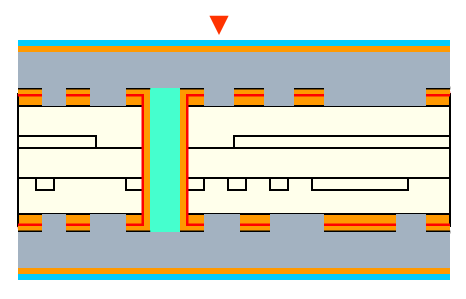

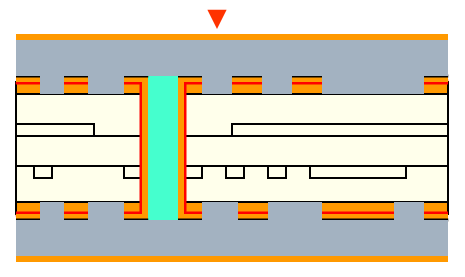

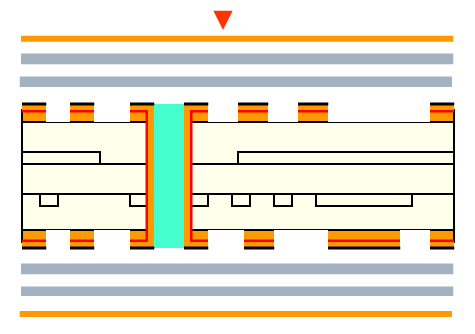

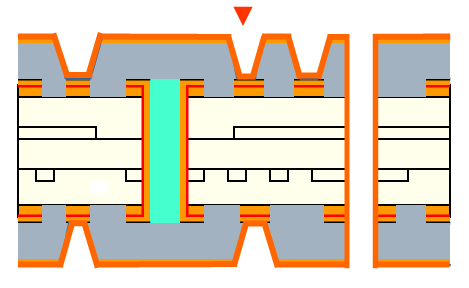

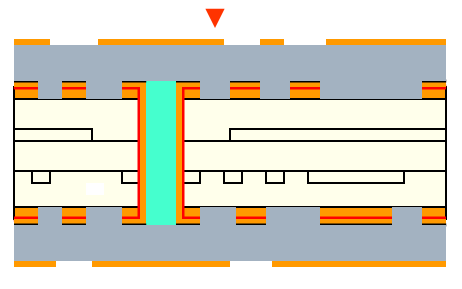

Blind & Burried 9+2+9 Laser Drill

|  |  |

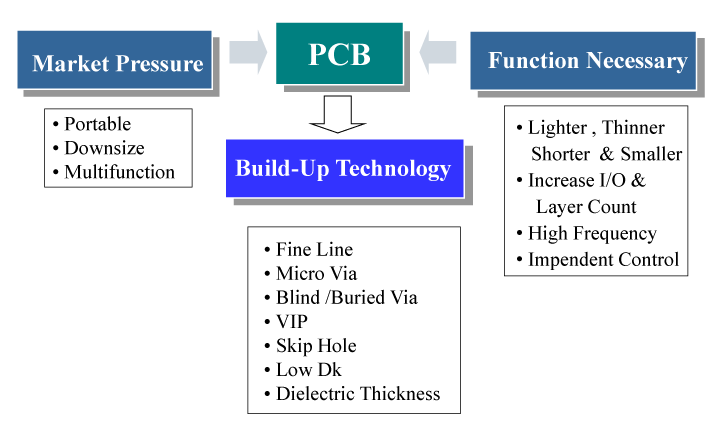

Market Trend vs. Technology Solution

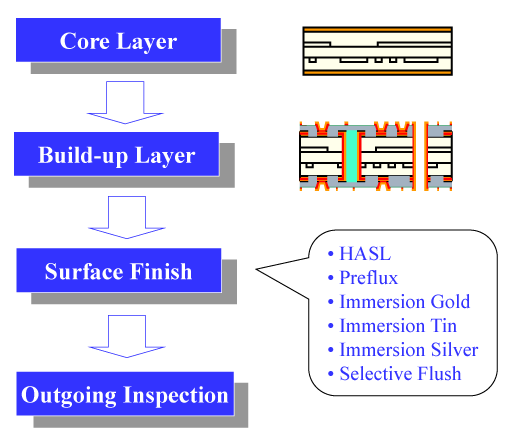

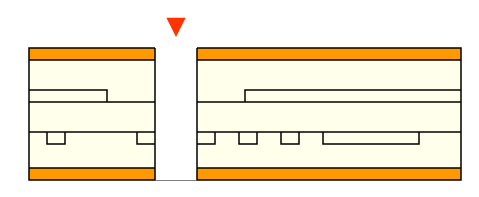

HDI Process Flow

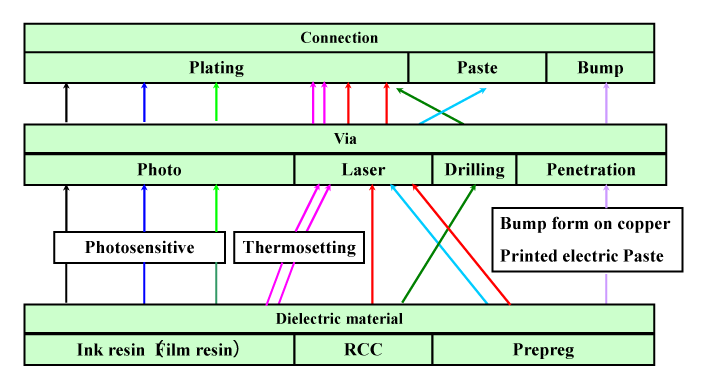

Main Process of Build – up Layer

Construction Materials

MATERIAL TYPE

- FR 4 Tetra Function ( Tg. 130 – 140 ℃ )

- FR 4 High Tg ( Tg. 160 – 180 ℃ )

- RCC ( Tg. 150 ℃ & Tg. 185 ℃ )

- Ink ( VIL )

Comparison of Material

| Prepreg | RCC | |

| Low Cost | ++ | – |

| Strength | ++ | + |

| Hole wall roughness | – | + |

| Laminating control | + | – |

| Dielectric thickness | 45um ~ | 30um ~ 80um |

| Smear residue on target pad | – | ++ |

| Dielectric constant | 3.9 ~ 4.7 | 3.2 ~ 3.8 |

| Shelf time | ++ | + |

| Working PNL size | ++ | + |

Comparison of Via Technologies

| Mechanical Drilling | Laser Drilling | |

| Low Cost in Equipment | ++ | + |

| Low Cost in Production | + | ++ |

| Required Facilities | Drilling Machine | Laser Machine |

| Consumable | Drill Bits, Backup Board | None |

| Aspect Ratio | 9 | 1 |

| Via Size Capacity | 200 um~ | 50~100um |

| Speed | 140 H/min | 20,000 H/min |

| Throughput | – | + |

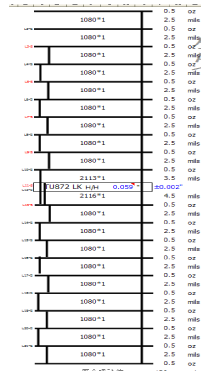

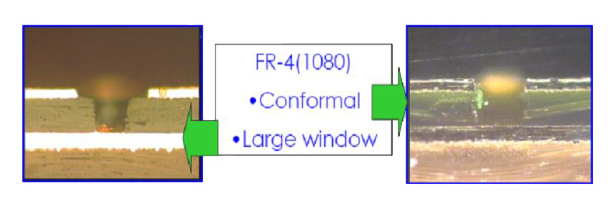

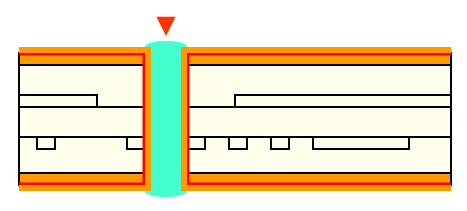

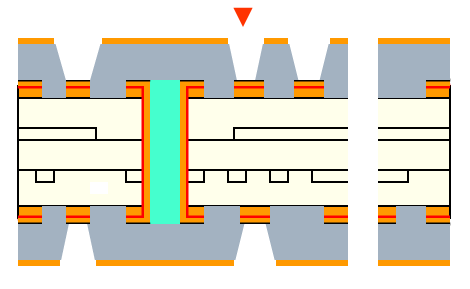

Comparison of Blind Via

| PREPREG | RCC |

|  |

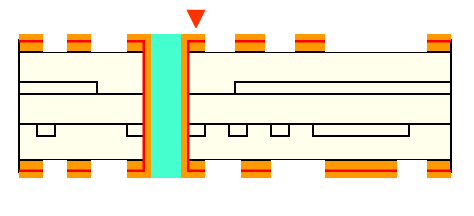

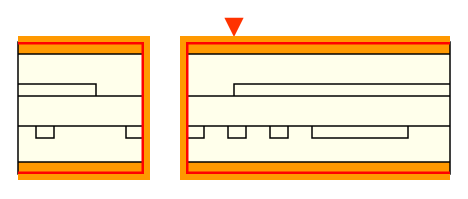

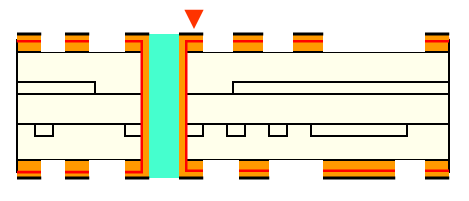

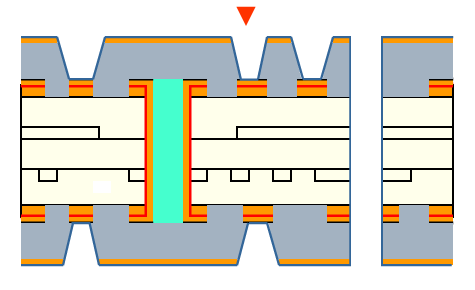

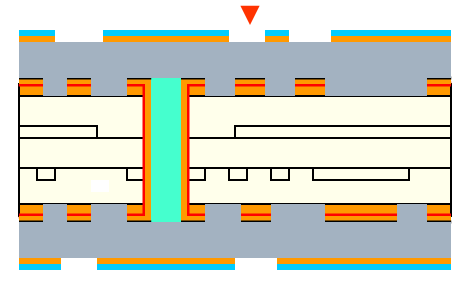

Build-up for 2 + N + 2

| THROUGH HOLE | INNER LASER VIA | STACK HOLE |

|  |  |

|

| INNER VIA HOLE | SURFACE LASER VIA |

|  |

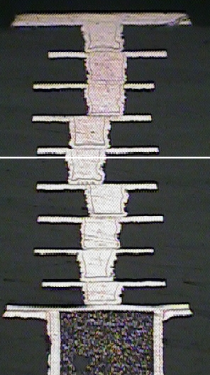

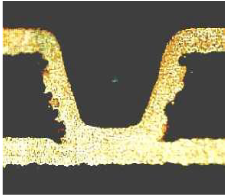

Laser Via Quality

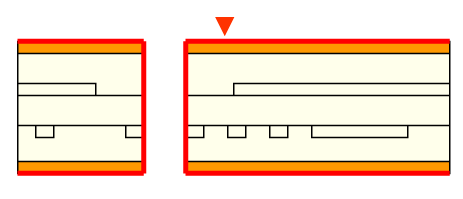

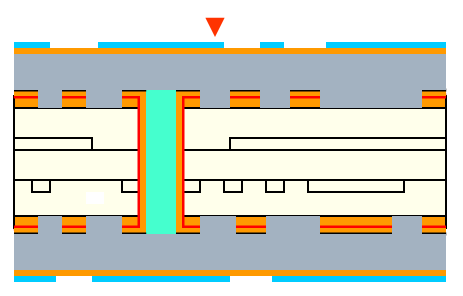

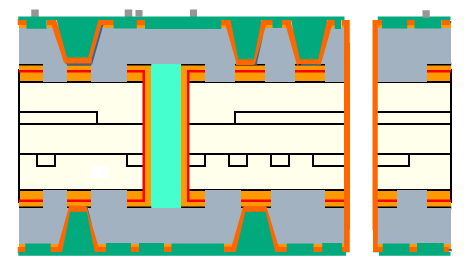

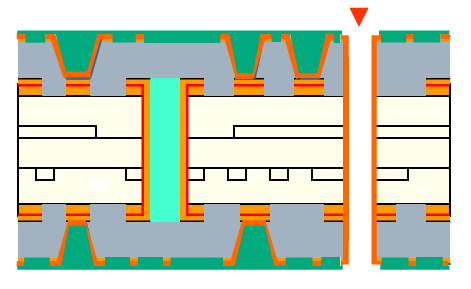

1+6+1 without buried, extend to 1+N+1

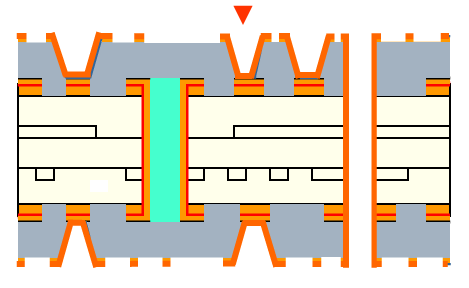

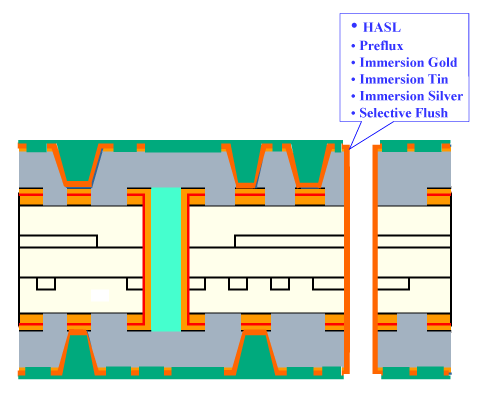

1+4+4+1 with buried via, extend to 1+N+N+1

Black Oxide Treatment

D.F. Strip

–

Etching

D.F. Exposure / Developing

Dry Film Lamination

I.V.H.Grinding( for thickness >= 60 mil )

I.V.H.Grinding( for thickness >= 60 mil )

Electro Plating

Electroless Copper Plating

I.V.H.(Inner Via Hole) Drilling

I.V.H.(Inner Via Hole) Drilling

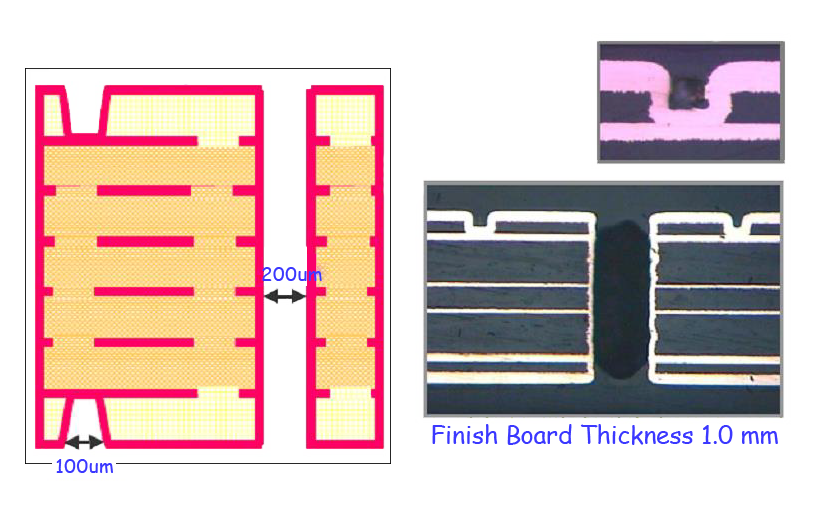

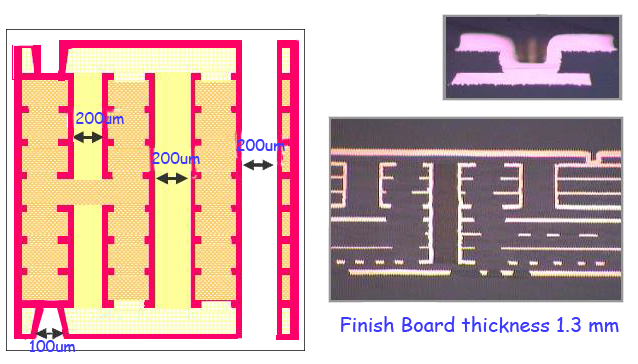

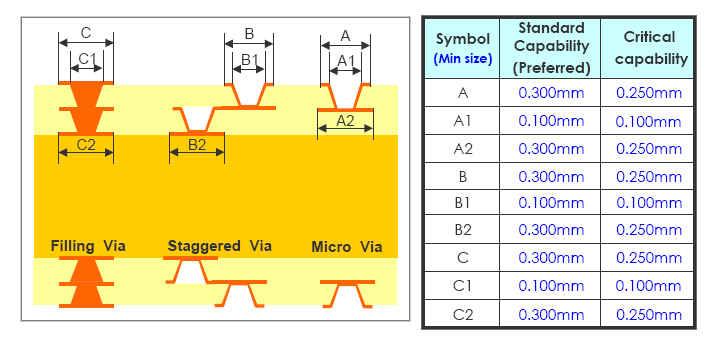

Blind via Capability

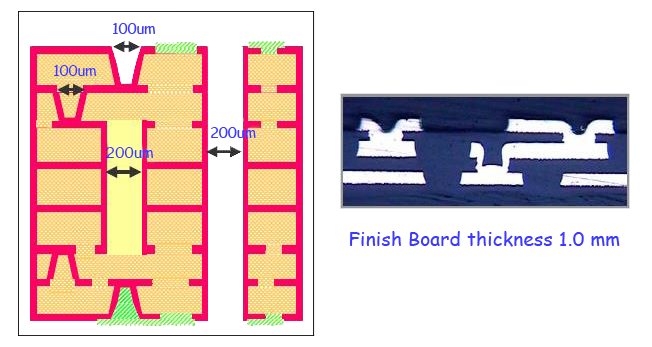

2+4+2 Staggered via, extend to 2+N+2

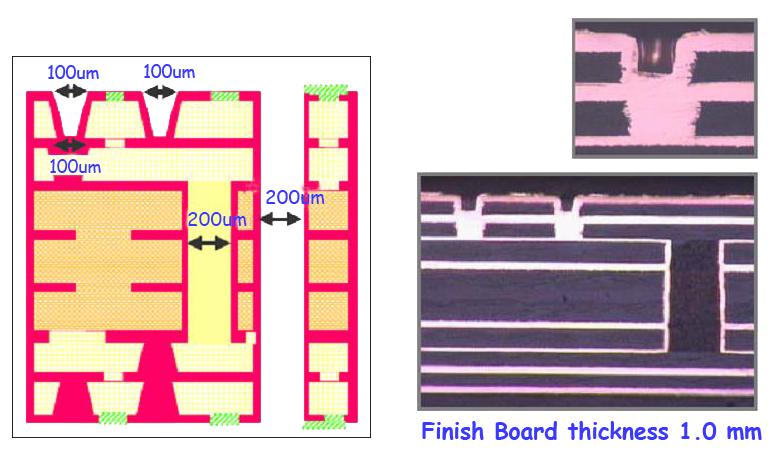

2+4+2 laser via on laser via

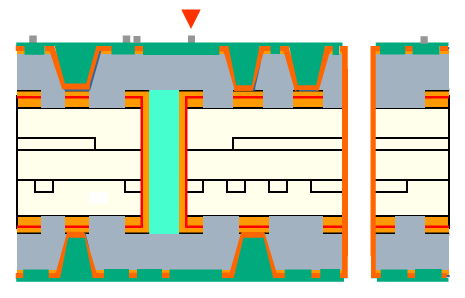

Solder Mask Printing

Dry Film Lamination

Lamination

Prepreg Layup

Black Oxide Treatment

D.F. Exposure / Developing

Dry film, Exposure & DES

Electro Plating

Desmear / Electroless Copper Plating

Laser Drilling for Blind Via

D.F. Strip

Etching

D.F. Exposure / Developing

–

S/M Exposure / Developing

Surface Finish

Symbol Mask Printing

Inspection

–