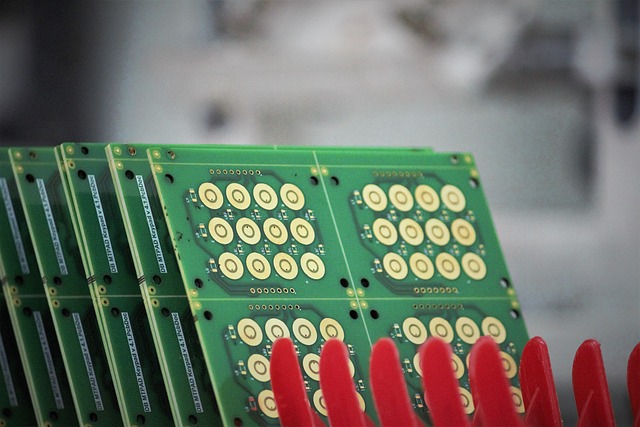

Single Sided PCB

PCB Trace Technologies Inc is one of the largest manufacturers of Single Sided Printed Circuit Boards or PCBs. These are a special type of circuit boards that have a printed circuit only on one side. The electronic industry uses single sided circuit boards commonly for simple and non-complicated circuit applications.

Depending on the application, we make various types of single sided PCBs. For instance, we make PCBs of different classes like 1, 2, and 3. The type of the board indicates its overall reliability and the quality of design:

- Class 1 PCBs are mostly for the consumer electronic industry.

- Class 2 PCBs are for devices that must be highly reliable, but not crucial.

- Class 3 PCBs are for devices that must not fail in the field, for example, in an airplane.

We also make three categories of single sided boards — rigid, flexible, and metal-core.

Rigid PCBs

These are the most common type of boards in the industry. These boards typically have a rigid substrate made from a lamination process using high heat and pressure. The common material that we use for these boards is FR-4. However, depending on the specific need of the application, we can modify the material to emphasize or improve certain characteristics of the substrate.

Flexible PCBs

As the name suggests, these boards are more flexible, allowing them to bend and deflect. The board thickness is far less than that of the standard rigid board, and the material is typically Polyimide, with an adhesive layer to bond a layer of copper foil. A flexible board has many advantages over rigid PCBs.

Metal Core PCBs

Metal Core PCBs are mostly rigid and made from a material that has an increased ability to conduct heat through the board to a metal core bonded to it. A special thin layer insulates and separates the PCB from the metal core. This layer has the special property of high heat conductivity but very low electrical conductivity. The industry uses metal core PCBs for applications that require heat dissipation from hot components during operation, such as high-wattage LED lighting.

Use of Single Sided PCBs

The industry uses single sided PCBs for mounting two types of components — through hole components and surface mount components.

For mounting through-hole components, the PCB requires holes drilled through the substrate. Through-hole components typically have long leads that require threading through these holes. The operator must mount the component such that its leads protrude through the board and on the side of the copper circuit. This allows the leads to be anchored to the copper circuit by a process called soldering. The operator then cuts off the extra leads.

For mounting surface mount components, no holes are necessary. A pick and place machine mounts the tiny surface mount components on the copper side directly. Before mounting the components, the operator must deposit a solder paste through a screen. The screen has openings in it to allow deposition of the solder paste only on the pads that will hold the component. Once the machine has placed all the components in their specific positions, the board will pass through a heating chamber, typically called the reflow oven. The hot environment in the oven will melt the solder paste and bond the component to the board.

Contact PCB Trace Technologies Inc for any requirement of single sided board for your application. We offer the best prices and the least turn around time in the industry.